The manufacturing industry is undergoing a major shift driven by technology and the demand for efficiency and collaboration. Enter cloud manufacturing, the game-changer that is reshaping traditional processes of unstructured data management. Join us as we discover the transformative path of this industry as it harnesses the potential of cloud manufacturing for accelerated growth and groundbreaking innovation.

Manufacturing Through the Ages

Over the years, the manufacturing industry has undergone a profound transformation fueled by technological advancements, changing consumer demands, and globalization. This evolution has created new opportunities for manufacturers worldwide, and the industry has responded with various strategies to stay competitive and innovative.

The first phase of transformation focused on automation and robotics. Manual labor was gradually replaced by advanced machines and robots, offering improved precision, speed, and efficiency. This shift resulted in increased productivity, reduced labor costs, and enhanced product quality. Automation became pervasive, with automated assembly lines and computer numerical control (CNC) machines revolutionizing manufacturing processes. Digitization became a driving force in the industry’s next phase. Manufacturers integrated digital technologies into their operations, leveraging the Internet of Things (IoT) to collect real-time data from sensors and devices. This data-driven approach provided valuable insights into equipment performance, supply chain operations, and customer behavior. Manufacturers optimized processes, implemented predictive maintenance strategies and made informed decisions using the power of data.

Simultaneously, customization and personalization gained prominence. Consumers sought unique, tailor-made products, prompting manufacturers to adopt additive manufacturing technologies like 3D printing. This shift disrupted traditional mass production models, allowing for the on-demand production of highly customized items. Small-scale manufacturing and niche markets flourished as manufacturers embraced this trend. Supply chain optimization became a critical focus in the industry’s subsequent phase. Manufacturers embraced digital tools and analytics to improve supply chain visibility, enhance demand forecasting, and optimize inventory management. Digitization and advanced logistics technologies enabled faster order fulfillment, reduced lead times, and increased overall operational efficiency. Sustainability and environmental responsibility also emerged as key priorities as the industry became more conscious of its impact. Manufacturers recognized the importance of waste reduction, resource conservation, and minimizing their carbon footprint. They adopted green manufacturing practices, such as utilizing renewable energy sources, implementing recycling initiatives, and embracing circular economy principles for sustainable product lifecycles.

The manufacturing industry has undergone a remarkable transformation journey, achieving significant advancements in productivity, efficiency, and innovation. Manufacturers have successfully tackled challenges such as siloed systems, data fragmentation, and limited collaboration. The need for transformation has become imperative to ensure sustainable growth in a fiercely competitive market. With manufacturers embracing emerging technologies and staying adaptable to evolving market dynamics, the industry stands at the cusp of transformative changes that will shape its future. Among these technologies, Cloud Manufacturing emerges as a prominent game-changer.

What is Cloud Manufacturing?

Cloud Manufacturing is a revolutionary approach that’s transforming the manufacturing industry as we know it. By harnessing the power of cloud computing, data analytics, the Internet of Things (IoT), artificial intelligence (AI), and automation, this leading edge technology is taking productivity, collaboration, and efficiency to new heights.

Imagine being able to scale your manufacturing operations with just a few clicks, adapting swiftly to market changes, and optimizing resource allocation on the fly. With cloud manufacturing, this becomes a reality. The seamless connectivity offered by cloud-based platforms allows manufacturers to collaborate in real-time with suppliers, partners, and customers, sparking innovation and streamlining the entire supply chain. Say goodbye to delays and hello to improved production planning, reduced lead times, and customers who can’t help but be impressed. Additionally, data analytics takes center stage in cloud manufacturing, providing manufacturers with valuable insights for data-driven decision-making, process optimization, and predictive maintenance. By tapping into the power of big data and analytics, manufacturers gain a deeper understanding of their operations, uncover patterns, and discover opportunities for improvement. It’s like having a crystal ball that helps you make proactive decisions, improve quality control, and boost operational efficiency.

And here’s the best part: cloud manufacturing is cost-effective! It eliminates the need for costly on-premises infrastructure, slashing upfront capital investments and ongoing maintenance expenses. Manufacturers can simply tap into cloud-based resources as they need them, paying only for the services they require. This scalability and cost-efficiency level the playing field, allowing large and small manufacturers to compete effectively and stay ahead of the game. Cloud manufacturing also has a green side. By optimizing resource utilization and energy efficiency, it promotes sustainability and reduces environmental impact. With cloud-based resources at their fingertips, manufacturers can manage their production processes with precision, minimize waste, and contribute to responsible manufacturing practices. It’s a win-win situation for both the business and the planet.

Here are some examples of companies that have successfully adopted cloud manufacturing:

- General Electric (GE): GE implemented cloud manufacturing to enhance operations and supply chain management. By utilizing cloud-based platforms, GE improved collaboration with suppliers and streamlined its production processes. This resulted in increased efficiency, reduced costs, and improved customer satisfaction.

- Adidas: The renowned sportswear company Adidas leveraged cloud manufacturing to optimize its production processes and enhance product customization. By integrating cloud-based platforms with their manufacturing systems, Adidas enabled real-time collaboration with suppliers, improved demand forecasting, and accelerated time-to-market for customized products.

- Tesla: Tesla, the electric vehicle manufacturer, implemented cloud manufacturing to revolutionize its production operations. Cloud-based platforms allowed Tesla to manage its complex supply chain, monitor production processes remotely, and optimize resource allocation. This enabled them to scale up production efficiently and meet increasing customer demands.

- Flex: Flex, a leading electronics manufacturing services company, adopted cloud manufacturing to drive innovation and collaboration across its global operations. By leveraging cloud-based tools and platforms, Flex improved communication and coordination among its dispersed manufacturing sites, enabling efficient data exchange, real-time visibility, and streamlined production processes.

- Procter & Gamble (P&G): P&G embraced cloud manufacturing to enhance its supply chain management and improve collaboration with suppliers. By utilizing cloud-based platforms, P&G gained real-time visibility into its supply chain, enabling better demand forecasting, inventory optimization, and efficient coordination with suppliers, leading to improved operational efficiency.

5 Revolutionary Ways Cloud Manufacturing is Transforming Traditional Processes

- Connected Ecosystems: Cloud manufacturing enables the creation of interconnected ecosystems where manufacturers, suppliers, partners, and customers collaborate in real time. This trend facilitates seamless communication and data sharing, fostering innovation, optimizing the supply chain, and enhancing overall efficiency.

- Digital Twins: Digital twin technology is gaining traction in cloud manufacturing. It involves creating virtual replicas of physical assets, allowing manufacturers to monitor, analyze, and simulate their performance in real time. Digital twins enable predictive maintenance, remote monitoring, and optimization of production processes, resulting in improved productivity and reduced downtime.

- Edge Computing: As the IoT continues to expand, edge computing is becoming increasingly important in cloud manufacturing. Edge computing involves processing data at the edge of the network, closer to the data source, rather than sending it to a centralized cloud. This trend reduces latency, enhances real-time decision-making capabilities, and improves the efficiency of data-intensive applications in manufacturing.

- Additive Manufacturing: Also known as 3D printing, additive manufacturing is transforming production processes in cloud manufacturing. This technology allows manufacturers to create complex and customized parts on demand, eliminating the need for traditional manufacturing methods. Additive manufacturing enables rapid prototyping, reduces material waste, and opens up new possibilities for product design and customization.

- Cybersecurity: With the increased reliance on cloud computing and connected systems, cybersecurity has become a critical concern in cloud manufacturing. Manufacturers are investing in robust cybersecurity measures to protect their sensitive data, intellectual property, and production systems from cyber threats. This trend involves implementing advanced authentication protocols, encryption techniques, and continuous monitoring to ensure data privacy and system integrity.

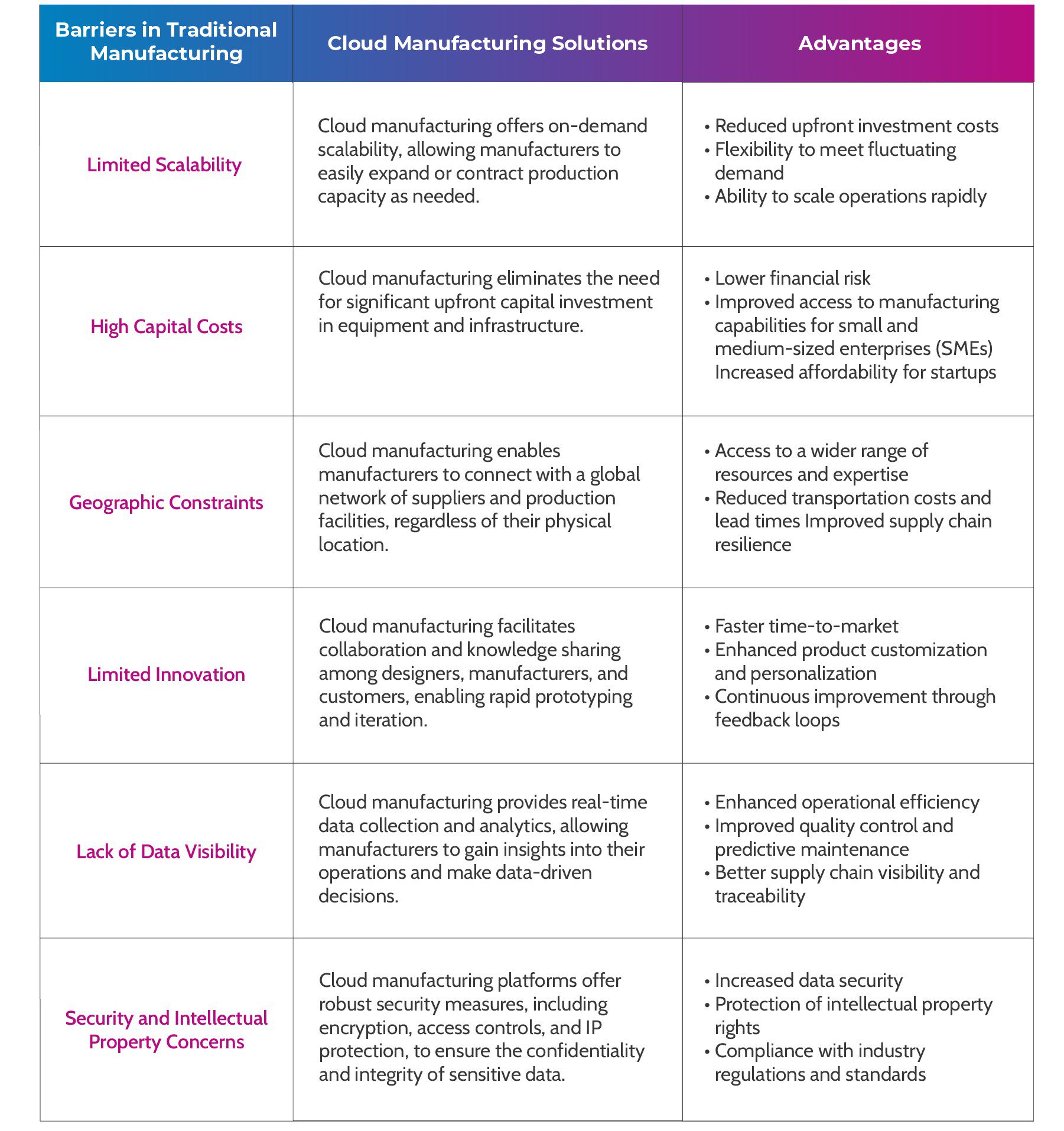

Unleashing the Potential: Cloud Manufacturing vs. Traditional Manufacturing

Microsoft Azure: Your Partner of Choice

Microsoft Corporation, a global tech giant, stands at the forefront of technological innovation. Renowned for its cutting-edge software products like the widely used Windows operating system and the acclaimed Microsoft Office suite, the company has expanded its horizons into the realm of cloud computing with its Azure cloud platform. As manufacturers strive for groundbreaking levels of agility, efficiency, and collaboration, Microsoft Azure emerges as an indispensable catalyst for their transformative journey.

Outlined below are some notable Azure tools that prove invaluable in the manufacturing industry’s transition to cloud manufacturing:

- Azure IoT Hub: Azure IoT Hub enables manufacturers to securely connect, monitor, and manage their IoT devices and sensors. It provides bi-directional communication between devices and the cloud, allowing real-time data ingestion and remote device management. Manufacturers can leverage Azure IoT Hub to collect and analyze data from their manufacturing equipment, enabling predictive maintenance, optimizing performance, and improving operational efficiency.

- Azure Digital Twins: Azure Digital Twins is a platform that allows manufacturers to create comprehensive digital representations of their physical assets, processes, and facilities. It enables manufacturers to model and simulate their production systems, monitor real-time data from connected devices, and gain insights for optimizing operations, improving energy efficiency, and enhancing asset performance.

- Azure Machine Learning: Azure Machine Learning is a cloud-based service that empowers manufacturers to build, deploy, and manage machine learning models. It enables manufacturers to leverage their data for predictive analytics, quality control, demand forecasting, and process optimization. Azure Machine Learning provides a collaborative environment for data scientists and engineers to develop and operationalize machine learning solutions.

- Azure Data Lake Storage: Azure Data Lake Storage is a scalable and secure data storage solution that allows manufacturers to capture and store large volumes of manufacturing data. It enables data ingestion from various sources, such as IoT devices, sensors, and production systems. Manufacturers can leverage Azure Data Lake Storage for data exploration, analytics, and building data pipelines to derive valuable insights and support decision-making processes.

- Azure Functions: Azure Functions is a serverless computing service that enables manufacturers to run event-driven code and automate tasks in response to specific events or triggers. It offers a lightweight, scalable, and cost-effective approach for executing business logic and process automation in the manufacturing environment. Manufacturers can utilize Azure Functions to build event-driven architectures, automate workflows, and integrate with other Azure services.

- Azure Logic Apps: Azure Logic Apps provides a low-code development platform for creating workflows and integrating applications, systems, and data sources. Manufacturers can leverage Azure Logic Apps to orchestrate complex manufacturing processes, automate data exchange between different systems, and streamline supply chain operations. It offers pre-built connectors and templates for seamless integration with various applications and services.

While the allure of cloud technology is undeniably captivating, the initial step in its adoption revolves around data migration. Organizations must seamlessly and accurately transfer their data to the cloud, ensuring a repeatable process. Unfortunately, manual procedures and budget constraints can impede the progress of cloud initiatives. To successfully migrate critical applications such as virtual desktops, virtual servers, high-performance computing, and analytics to the cloud, the transfer of data from file servers, NAS appliances, and Object Storage becomes imperative, ranging from tens of terabytes to several petabytes. However, navigating the complexities and risks of migrating file data across diverse platforms can be daunting. What we truly need are solutions that are automated, intuitive, and scalable, effectively circumventing these challenges.

With the Azure File Migration Program, Microsoft has made the journey easier. Through the use of Data Dynamics’ StorageX for migrating data into Azure, Microsoft enables organizations to migrate unstructured files and object storage data into Azure at no additional cost or licensing. Customers can register their migration project information with Data Dynamics and start moving data today. StorageX is Data Dynamics’ leading unstructured data migration software delivering automated policy-based data migration. StorageX enables seamless cloud data migration, data center consolidation, and storage optimization to drive intelligent, swift, and secure petabyte-scale unstructured data migrations.

Through this program, Microsoft and Data Dynamics aim to help organizations address some of their most critical challenges in the cloud migration lifecycle, such as cost, speed, talent, and risk. Click here to know more. Or contact us at solutions@datdyn.com I (713)-491-4298.

You can also visit our website at www.datadynamicsinc.com to know more about our unified data management platform – a one-stop solution for Mobility, Analytics, Security, and Compliance.